Latte Maker

Intro to Robotics and Mechatronics

The Project:

This will be a fully robotic cafe that can take orders, make lattes, and deliver lattes to your customers. Aside from the customers placing and receiving orders, there should be as little human involvement in your cafe operations as possible.

Budget: $500

Provided Supplies: Course Kits, Create 3 Robots, Espresso Capsules & Espresso Machine

Due: Tuesday, April 23rd at 12 PM

Constraints:

You must use one hardware or software component from every project we have done so far

You cannot use hot glue or tape in the final demo

How It Worked:

We split up the latte maker into 4 groups:

Trasport

Coffee

Milk

Art

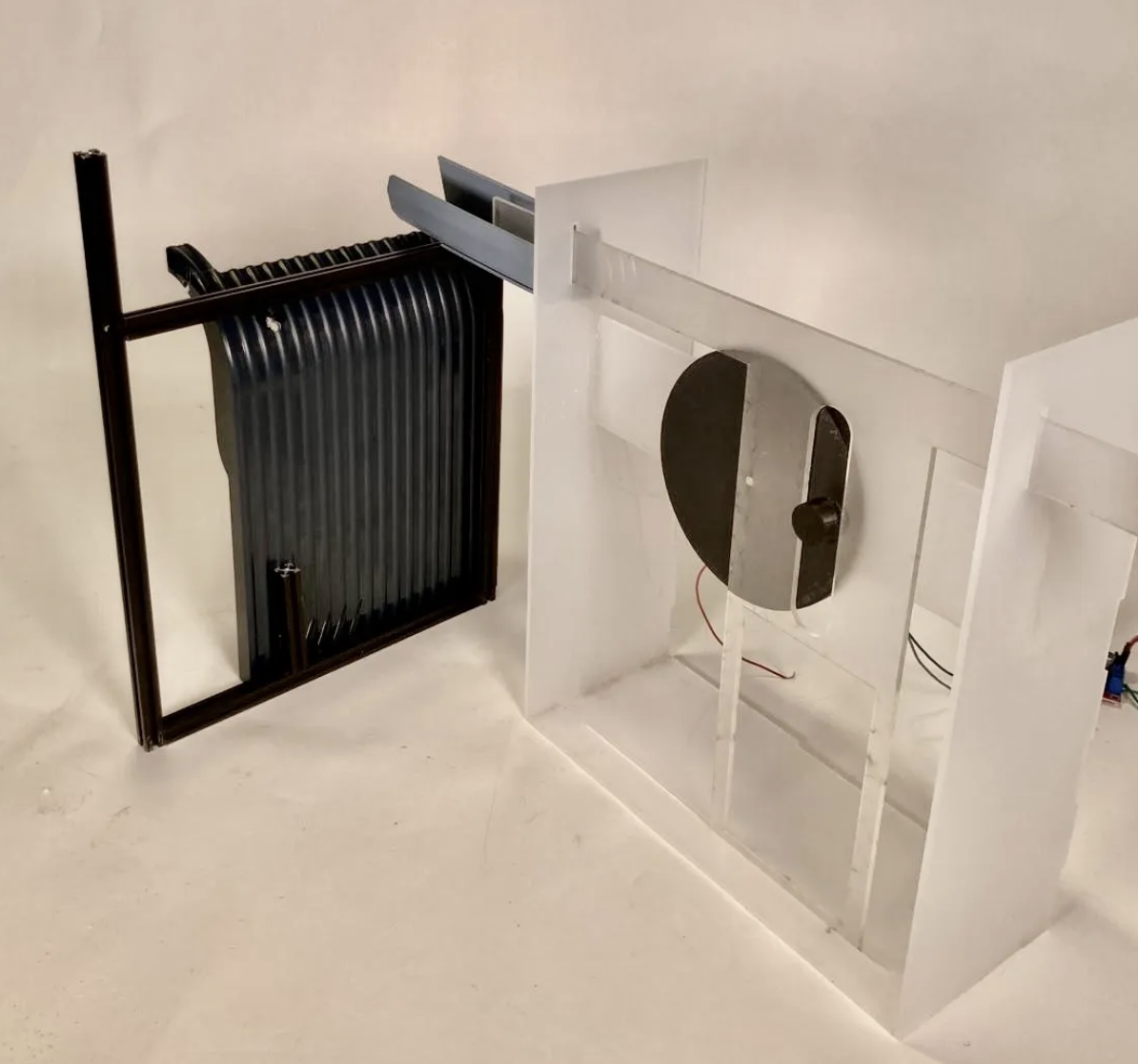

We utilized a Create3, functioning as a lazy Susan, to seamlessly transport the cup through each station before presenting it to the customer. First, an interface featuring a Pi camera which used Machine Learning enables customers to select their preferred artwork for their latte, followed by choosing between a single or double shot of espresso. Subsequently, the Raspberry Pi relayed these choices to an Airtable, initiating the process.

Firstly, a cup was dispensed into the initial slot of the lazy Susan, which then rotated to the coffee station. Here the coffee maker lid opened, the espresso pod was inserted, the lid closed, and the brewing process was initiated. After a minute, the brewed coffee flowed into the awaiting cup. Upon completion, the Airtable was notified to proceed to the next step: milk.

At the milk station, milk was pumped into the frother, frothed, and poured into the cup. Once this step concluded, the Airtable was updated and the system advanced to the art station. Here, the previously selected stencil was positioned over the cup, and cinnamon was dispersed. Once this was completed, the Airtable received a final notification, prompting the lazy Susan to move to its ultimate destination, where the customer could retrieve their customized coffee.

My Section: Coffee Pod

I was part of the Coffee Pod team, consisting of four students assigned with the challenge of loading three pods into the coffee machine. The project aimed to achieve the production of three lattes autonomously, hence the objective of loading three pods without human intervention.

Linear Motion:

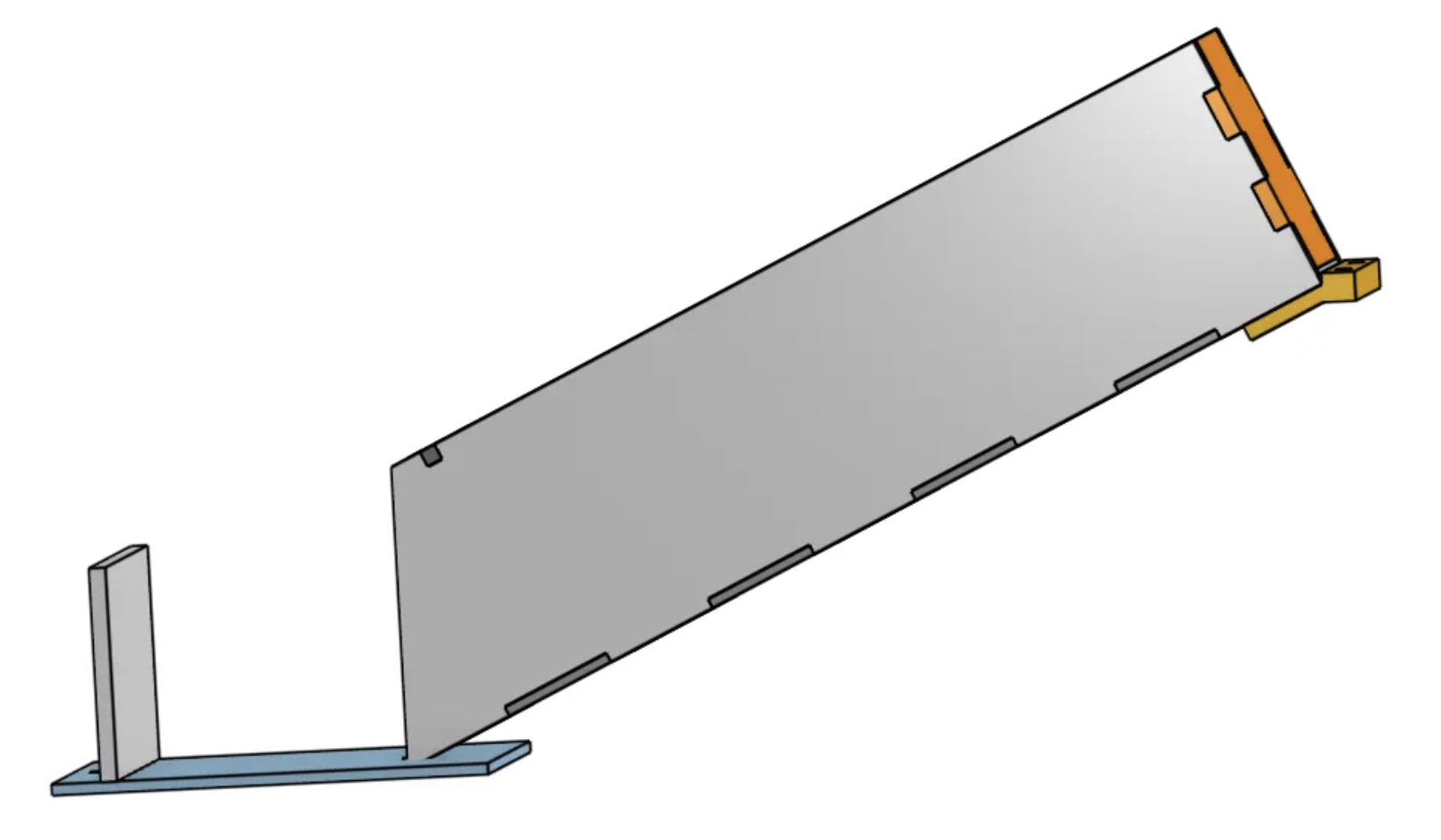

We employed a Scotch and Yolk mechanism to convert the linear motion of the stepper motor into the linear motion required to push the pods into the machine's hole. This linkage system was chosen for its potential to provide precise control over the distance the pods were pushed. Half of the circular disk's rotation represented the extent to which we could push the pods. To accommodate the need for three separate pushes, we divided this half rotation into three segments. The inclusion of a fourth pod was necessary due to the slightly insufficient linear motion; by adding the fourth pod, we ensured successful insertion of three pods.

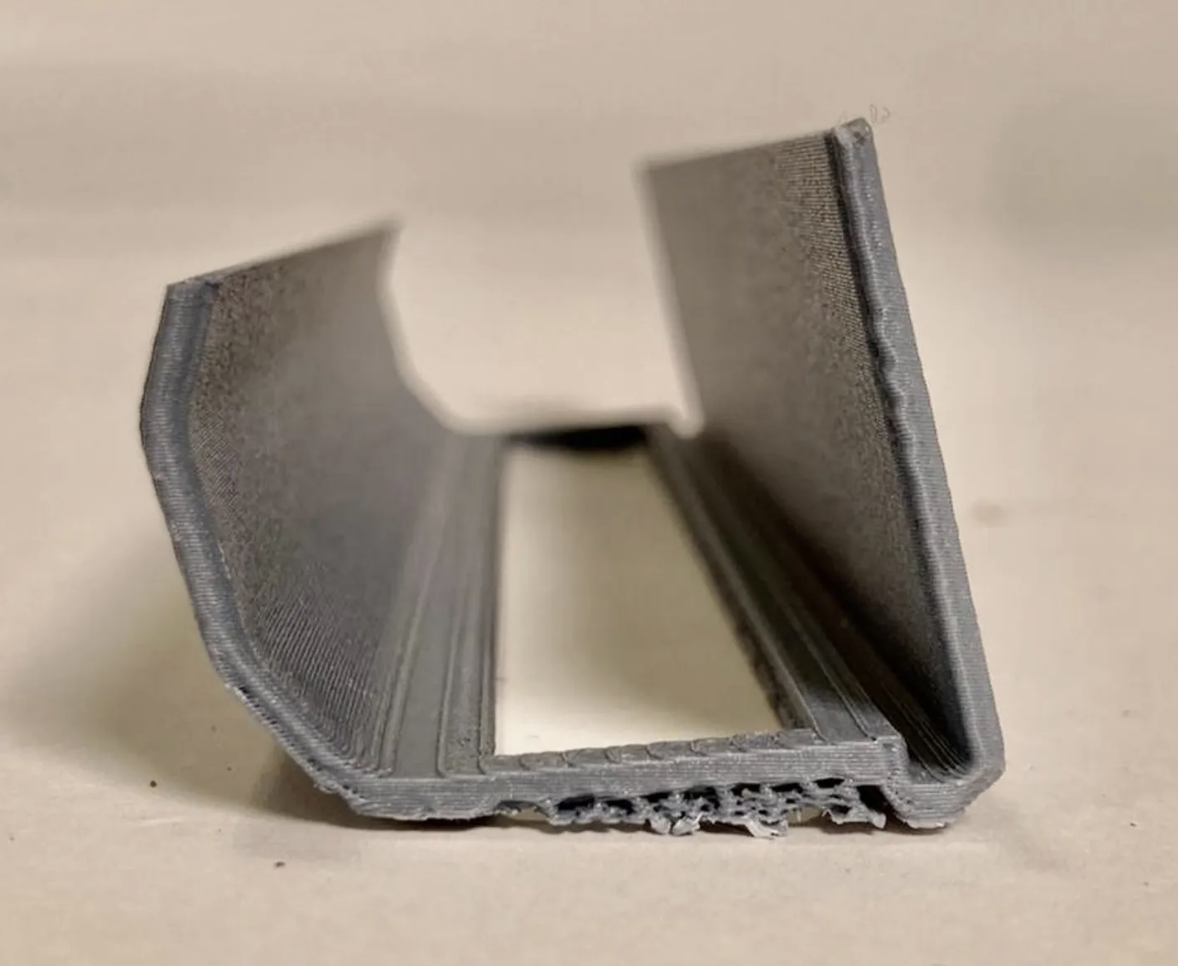

We also played around with how we are pushing the pods. Our original idea was to cup the pod from both sides but once we changed our design from the ramp to the flat tunnel we kept it simple and just used the flat edge of the laser cut scotch and yolk mechanism.

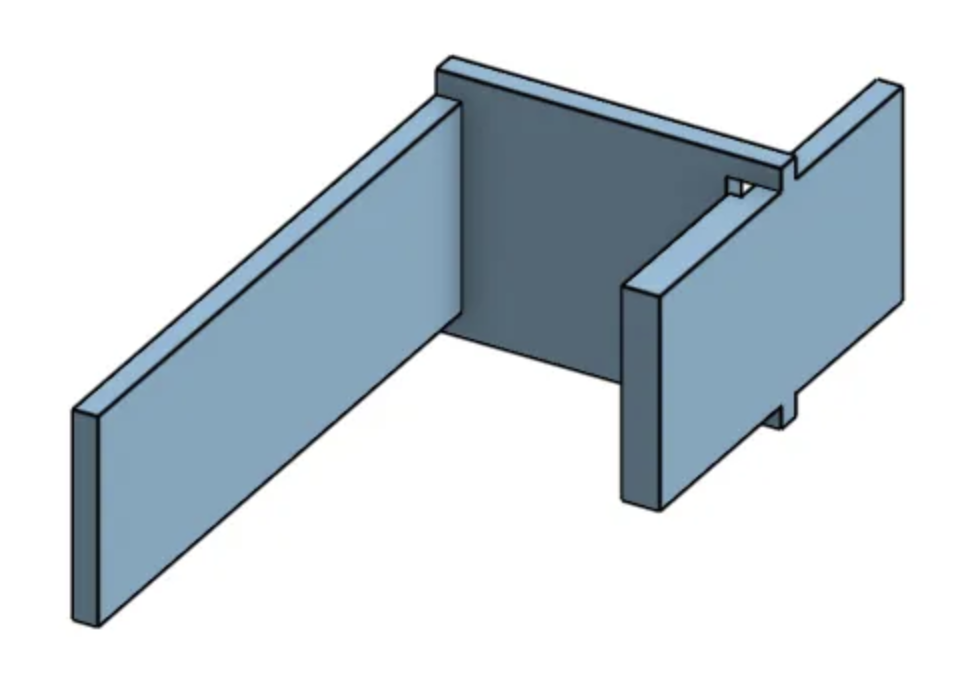

Pod Holder:

We created a tunnel that holds the pods. We took the side profile of the pod and made that the shape of the tunnel. This tunnel was then attached used maker beams to the side of the coffee maker. This piece had to be perfectly lined up with the pod hole so that when the scotch and yolk mechanism pushes the pods it can fall perfectly in the hole.

Our original idea was to have the pods slide down a ramp using gravity and then have the pod at the bottom would get pushed into the coffee machine. We ran into the issue that the pods wouldn’t uniformly fall down the ramp and the next pod would get stuck in the pusher while the current one is being pushed. This design was similarly attached to the side of the coffee machine.

Reflection:

In the end, we successfully achieved our class goal of crafting a latte, and I'm delighted with the final outcome. Reflecting on the process, I now see that inserting the pods into the coffee maker was one of the most challenging tasks due to its precision requirement. Initially, my team and I underestimated this aspect. We continuously made design adjustments until we ensured that we could consistently insert three pods every time we operated it. Our journey involved extensive rapid prototyping and improvisation, utilizing materials like scrap materials, popsicle sticks, and copious amounts of tape until we devised a functional design. Initially, we attempted to over-engineer the solution with a ramp. However, once it became evident that the ramp was impractical, we stepped back and quickly streamlined our approach. Soon enough, the tunnel was operational without any hitches.